Shandong Tonglida Heavy Industry Machinery Co., Ltd. is a

professional company that produces and manufactures a variety of

water treatment equipment, national “high-tech enterprises”,

national “an enterprise and a technology innovation enterprise”.

Our company is a member of the Water Treatment Association,

providing various water treatment equipment and solutions to meet

the requirements of different industries. Our company has many

patented technologies and soft writings of scientific and

technological research results. Its the internship base of Shandong

University of Science and Technology. ISO9001 quality system

certification has been passed by our company.

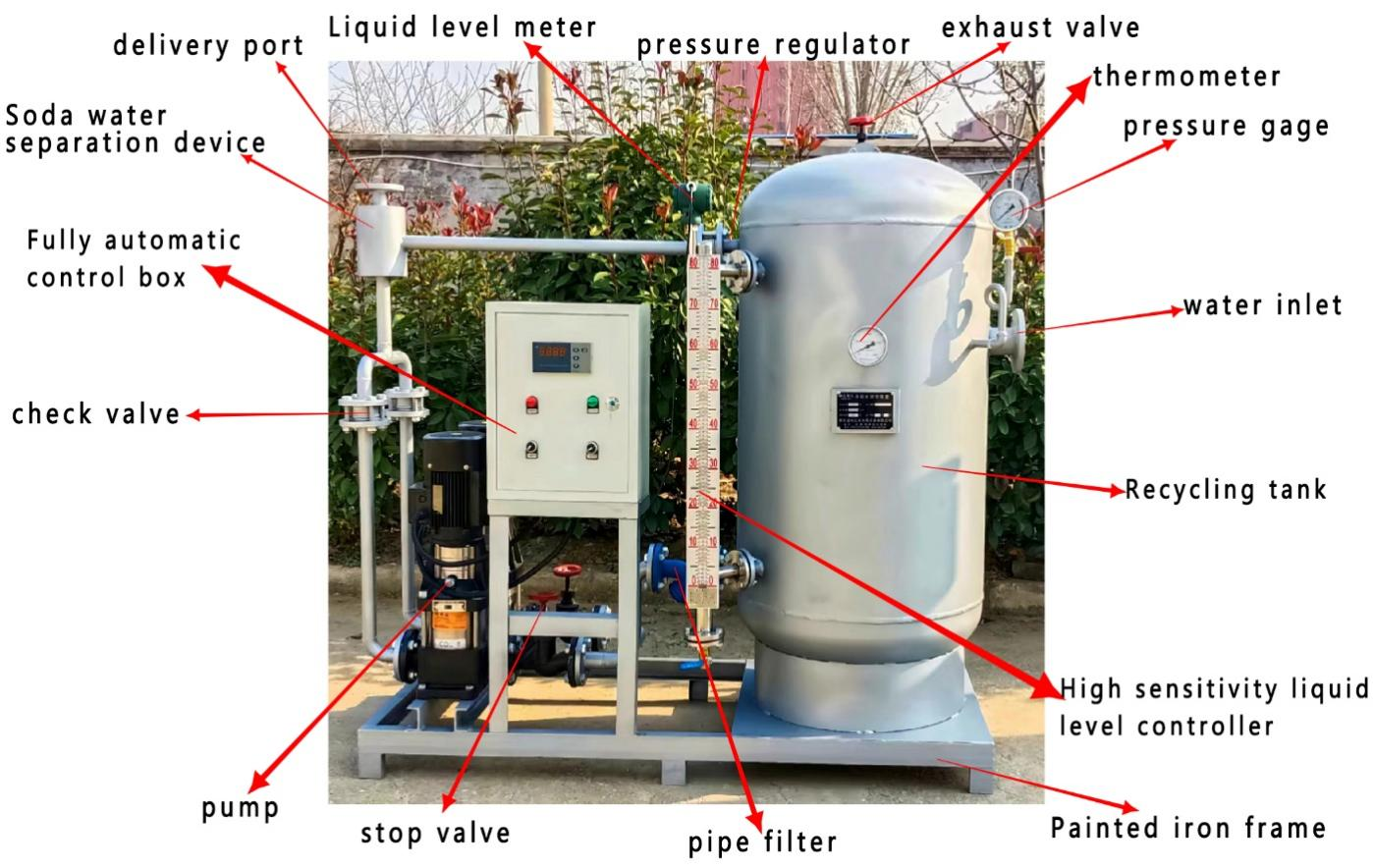

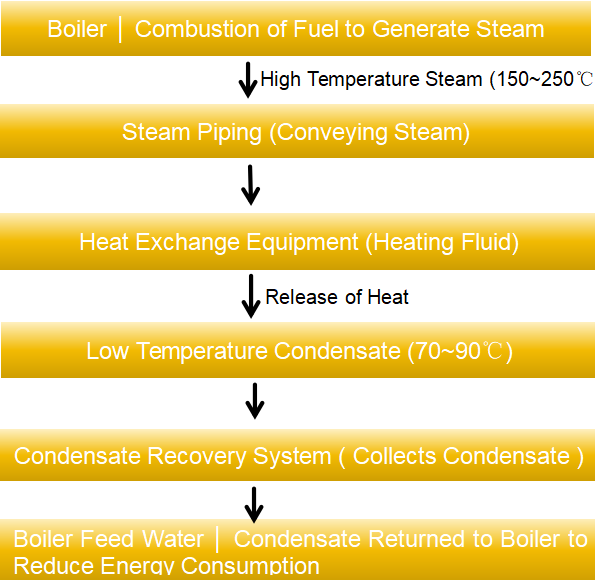

Our company's main products are: Condensate Recovery Devices,

Reverse Osmosis Equipment, Industrial Sand Filter, Fully Automatic

Water Softener, Water Supply Equipment, Chemical Dosing Device, Air

Compressor Heat Recovery, Water Treatment Accessories, Container

Flipper, Container Loading And Unloading Machine, Truck Flipper,

Electric Transfer Cart, Electric Weight-bridge, Mobile Loading Dock

Ramp etc.

Our products are known for their reliable performance, easy

installation, competitive pricing, and have been widely

promoted and applied domestically and internationally.

We undertake complete sets of water treatment engineering

design, manufacturing, installation, service, training, etc.

Our mission is to lead the industry with cutting-edge water

treatment technology to help our customers meet their toughest

water quality challenges.

Our vision is to create a clean, safe world where future

generations can enjoy pure water.

Our enterprise purpose is to "continuously improve product quality

and provide excellent after-sales service." We are committed to

offering advanced technology, high-quality products, reasonable

prices, and satisfactory services. We sincerely look forward to

cooperating with you.